Valves

Filters

Latest Products

-

Medium duty steel castor

Medium duty steel castor

-

Light duty steel castor

₹ 10,000.00

Light duty steel castor

₹ 10,000.00

-

Cast iron track wheel (FLG)

₹ 10,000.00

Cast iron track wheel (FLG)

₹ 10,000.00

-

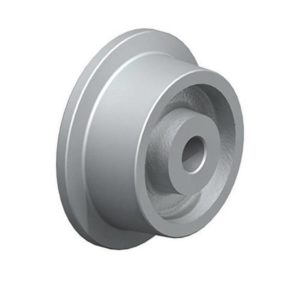

Cast iron track wheel

₹ 10,000.00

Cast iron track wheel

₹ 10,000.00

-

Cast iron track wheel

₹ 10,000.00

Cast iron track wheel

₹ 10,000.00

Showing 1–12 of 14 results

-

SKU: V-PN 10Rated 0 out of 5

Aquaseal10 Integrally-moulded Wafer-type Butterfly Valve is available in sizes from 50 mm (2”) to

600 mm (24”), in PN 10 pressure rating. The valve was developed to provide reliable sealing in water

and air lines, and is today the industry benchmark.

The most striking feature of Aquaseal10 Butterfly Valve is its integrally-moulded body liner.

Aquaseal’s elastomer body seat is vulcanised insitu onto the body using high temperature and

pressure, and this provides longer life and superior performance when compared to valves with loose

liners.

Aquaseal 10 requires no maintenance, and is truly a fit-and-forget valve -

SKU: V-PN 16Rated 0 out of 5

Aquaseal 16 Integrally-moulded Butterfly Valve sets a new benchmark in performance for butterfly

valves. The versatile valve is offered in a variety of elastomer-disc combinations to address myriad

process requirements. The highly reliable butterfly valve has successfully completed over 10,000

cycles at its rated pressure.

Available in sizes from 50 mm (2”) to 900 mm (36“), the valve is available in Cast Iron, SG Iron

and carbon steel, in a variety of body styles, materials and actuation options. The body seat of

Aquaseal16 Butterfly Valve is vulcanised insitu onto the body, which provides longer life and superior

performance when compared to valves with loose liners. -

SKU: V-PN 10-1Rated 0 out of 5

Aquaseal Fab Chek Fabricated Steel Check Valve compliments Aquaseal

Max Large-size Fabricated Steel Butterfly in water distribution systems and

power plants. The valve is fabricated from carbon steel plates, and body

and disc seats are hard-faced using 13% Cr steel.

Smooth closure of the valve is ensured by using a counter weight. The

valve can be supplied with hydraulic dash pot to prevent disc slamming

and water hammer. Automated Fab Chek can also be used as combined

shut-off and non-return valve on pump discharge lines.

The valve is available in PN 6, PN 10 and PN 16 pressure ratings, with

flanged ends -

SKU: KT-V6Rated 0 out of 5

(Screwed)

SALIENT FEATURES :

Screwed in Bonnet, Piston Type with a provision of installing pressure gauge at down

stream side, Screwed female ends to BS 21.TEST PRESSURE

(Hydraulic) 21.1Kg/cm? -

SKU: KT-V12Rated 0 out of 5

S.S. 410 Stem with Bronze Working parts.

Conforming to IS 14846 PN1L6, PD type Flanged ends

as per IS 1538 -

SKU: KT-V4Rated 0 out of 5

(Screwed)

SALIENT FEATURES :

Screwed in Bonnet,

2 Piece Design, Lever Operated with PVCSleeve. Screwed female ends to IS 554,

Conforming to IS 9890. — -

SKU: KT-V2Rated 0 out of 5

Water type, leaver/gear operated compatible to insertion between flnages of BS 10 , ASA class 150

Conforming to IS 13095 -

SKU: KT-V1Rated 0 out of 5

Straight pattern, stop type, nodular cast iron body, bronze trim, PN16, flanged

-

SKU: KT-V10Rated 0 out of 5

STRAIGHT PATTERN (Flanged)

SALIENT FEATURES :

Qutside Screw, Yoke type &

Rising stem with backseat arrangement, SS 410

Renewable Working Parts, Handwheel operated,

Straight Pattern. Design Standard BS5152,/ DIN 86251

Flanged ends as per DIN 2533 RF for PN-16

Sizes upto 150mm & DIN2532 RF PN-10 for 200mm.TEST PRESSURE

(Hydraulic) Seat: 16Kg/cm? Shell 24Kg/cm?

(Steam) Seat: 13Kg/cm? Max. Working Temp. 220° -

SKU: KT-V3Rated 0 out of 5

SALIENT FEATURES :

Bolted Bonnet, Non Rising

S.S. 410 Stem with Bronze Working parts.

Conforming to |S 14846 PN1L.6, PD type Flanged ends

as per IS 1538 -

SKU: KT-V9Rated 0 out of 5

SALIENT FEATURES :

Bolted Bonnet, Non Rising

S.S. 410 Stem with Bronze Working parts.

Conforming to IS 14846 PN1L6, PD type Flanged ends

as per IS 1538 -

SKU: KT-V7Rated 0 out of 5

VALVES THREE PIECE DESIGN (Screwed)

SALIENT FEATURES :

Bolted Connector, S.S, 304

Ball & Stem, Screwed Female Ends BSP taper

Threads to BS 21, Design Standard BS 5351

Full bore Three Piece Design.TEST PRESSURE

(Hydraulic) Seat :40 Bar, Shell: 76 Bar

(Steam) Seat:40Bar Max. Warking Temp. 425°

Showing 1–12 of 14 results