Pioneer

Filters

- Brandix (1)

- HVAC (12)

- Indef (8)

- Jindal (2)

- Kranti (11)

- L&T Valves (3)

- RedGate (1)

- Specter (1)

- Sunset (1)

- TurboElectric (2)

Latest Products

-

Medium duty steel castor

Medium duty steel castor

-

Light duty steel castor

₹ 10,000.00

Light duty steel castor

₹ 10,000.00

-

Cast iron track wheel (FLG)

₹ 10,000.00

Cast iron track wheel (FLG)

₹ 10,000.00

-

Cast iron track wheel

₹ 10,000.00

Cast iron track wheel

₹ 10,000.00

-

Cast iron track wheel

₹ 10,000.00

Cast iron track wheel

₹ 10,000.00

Showing 1–12 of 14 results

-

SKU: W-R2Rated 0 out of 5

Agood quality rubber compound bonded ( molded ) over a cast iron core forms a Bonded

Rubber Tyre Wheel. The load carrying capacity as well as life of BRT wheel is much more

than that of SRT wheel. Castings can be returned back to us for re-bonding of rubber

when it is worn out.Hardness of Rubber : (85 ± 5 ) on Shore ‘A’ scale.

Grade of the casting : FG 200 as per IS-210

0 Maximum Working Temperature : 50 C -

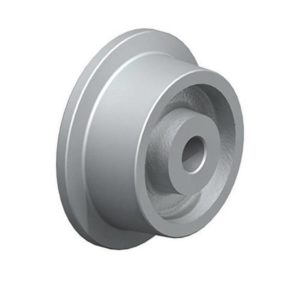

SKU: W-CI 2Rated 0 out of 5

Cast Iron wheels with either V-groove (VG), Square groove

(SQG), or a Flange (FLG) are available depending upon the track

over which the castors has to move. Since the wheels roll over

steel track, the pushing or pulling force required is much less,

reduces labour fatigue. Floor surface also does not get damage

at any timeDiamensional details of V-groove, Square groove and Flange for

wheels having 25 mm width, 32 mm width and 50 mm width are

as per drawings given.

Grade of Casting : FG 200 as per IS – 210

0 Maximum Working Temp. : 250 C

Hardness of Casting : ( 175 ±10 ) BHN. -

SKU: W-CI 3Rated 0 out of 5

Cast Iron wheels with either V-groove (VG), Square groove

(SQG), or a Flange (FLG) are available depending upon the track

over which the castors has to move. Since the wheels roll over

steel track, the pushing or pulling force required is much less,

reduces labour fatigue. Floor surface also does not get damage

at any time. -

SKU: W-CI 6Rated 0 out of 5

Cast Iron wheels with either V-groove (VG), Square groove

(SQG), or a Flange (FLG) are available depending upon the track

over which the castors has to move. Since the wheels roll over

steel track, the pushing or pulling force required is much less,

reduces labour fatigue. Floor surface also does not get damage

at any time.Hardness of Casting : ( 175 ±10 ) BHN

Grade of Casting : FG 200 as per IS – 210

0 Maximum Working Temp. : 250 C -

SKU: W-CI 8Rated 0 out of 5

Cast Iron wheels with either V-groove (VG), Square groove

(SQG), or a Flange (FLG) are available depending upon the track

over which the castors has to move. Since the wheels roll over

steel track, the pushing or pulling force required is much less,

reduces labour fatigue. Floor surface also does not get damage

at any timeHardness of Casting : ( 175 ±10 ) BHN

-

SKU: W-CI5Rated 0 out of 5

These are bare cast iron wheels made from good quality graded casting, machinable &

free from blow holes. These wheels have very high load carrying capacity & are suitable

for high-temperature applications like ovens, foundries etc. The only disadvantage of CI

wheels is that they damage the costly floor surfaces.Grade of Casting : FG 200 as per IS – 210

0 Maximum Working Temperature : 250 C

Hardness of Casting : ( 175 ±10 ) BHN -

SKU: W-F1Rated 0 out of 5

These wheels are manufactured by compression molding shredded cotton fabric,

soaked in good quality phenolic resin. The hardness of fibre wheel is higher than the

hardness of UHMW wheel. As a result, the chances of steel burr lying on the shop floor

getting embedded in the wheel surface are remote. The acidic or alkaline chemicals have

little effect on these wheels.Hardness of Wheel : ( 90 ± 5 ) on Shore ‘D’ scale.

0 Maximum Working Temperature : 170 C -

SKU: W-CL 1Rated 0 out of 5

Light duty castors are suitable for hospital furniture, house hold furniture & equipments, laboratory equipments, food serving

trolleys in hotels & canteen etc. where weight of material to be carried is small. Light duty extra strength castors are particularly

suitable where LD castors fails too frequently & where loads are moderate. Both LD & LD-X castors looks like same. Only difference

is LD-X castors are manufactured from higher plate thickness.Light Duty Stainless Steel brackets are manufactured from stainless steel sheets (SS-304). All other components of bracket such as

kingpin, nut, D.P.cap, spring washer, bolt etc are also of stainless stee -

SKU: W-CL 2Rated 0 out of 5

Medium Duty castors are designed to carry moderate loads i.e. more than LD or LD-X castors, and are suitable for various types of

trolleys used in industries, warehouses, godowns, stores, railway platform and so on. These castors are also suitable for hospital

furniture, laboratory equipments or food serving trolleys where load carrying capacity required is higher & the light duty castors

need frequent replacement -

SKU: W-P10Rated 0 out of 5

These wheels are manufactured from virgin Nylon 6, white in colour, by injection molding.

These wheels are light in weight, but have high load carrying capacities. These wheels can be used up to 90 C temperature. The acidic or alkaline chemicals have no effect on

these wheels.

Hardness of Wheel : (90 ± 5) on Shore ‘D’ scale.

0 Maximum Working Temperature : 90 C -

SKU: W-P7Rated 0 out of 5

Polyurethane with high abrasion resistance, mechanically locked over a polypropylene

core, forms a PU-PP wheel. PU-PP wheels are manufactured by injection moulding

process. The load carrying capacity as well as life of wheel is much more than that of SRT

wheel. PU wheels have good shock absorption capacity & very low noise level.Hardness of Polyurethane : (94 ± 5) on Shore ‘A’ scale.

0 Maximum Working Temperature : 50 C -

SKU: W-P8Rated 0 out of 5

Polyurethane with high abrasion resistance bonded ( molded ) over a cast iron core forms

a PU-CI Wheel. PU-CI wheels are manufactured by casting process. The properties of

cast polyurethane are much better than that of injection moulded polyurethane. The load

carrying capacity as well as life of wheel is more than that of PU-PP wheel. PU-CI wheels

have good shock absorption capacity & very low noise level.Hardness of Polyurethane : (94 ± 5) on Shore ‘A’ scale.

0 Maximum Working Temperature : 50 C

Showing 1–12 of 14 results